How to choose a hammer crusher

High-efficiency pulverizer: The Preferred Choice for Productivity

1. High pulverization efficiency: The optimized design makes the pulverization speed 30%-50% faster than traditional models

2. Convenient screen replacement: Special structural design allows screen changes in just 5-10 minutes.

3. Lowerenergy consumption:Saves around 20% in electricity usage per unit output compared to conventional models.

Applicable materials:

Wood Biomass: wood, straw, bamboo, grass and other biomass raw materials

Feed:corn, wheat and other grain raw materials, as well as some chemical raw materials

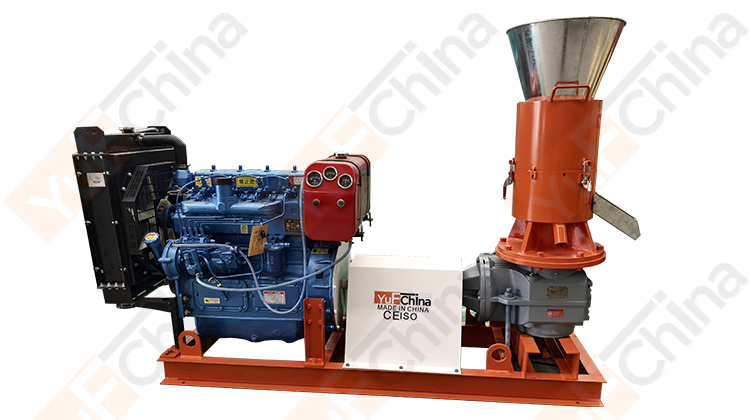

Multi-functional Crusher: A Traditional and Reliable Choice

Advantages:

1.High versatility:Capable of processing various types of materials.

2.Simple structure:Low technical requirements for maintenance.

3.Cost-effective:Lower initial investment cost.

Applicable materials: wood, straw, bamboo, and other biomass raw materials

Other common types of crushers

1. Blade crusher: specially designed for fibrous materials to keep the fiber structure intact

2. Mobile crusher: dedicated to construction waste treatment, can be operated on-site

Purchase suggestions

1. First clarify the material characteristics: hardness, moisture content, fiber content, etc.

2. Consider production needs: choose high-efficiency type for large-scale production, and choose multi-functional type for small-scale and multi-variety production

3. Prioritize after-sales service: understand the manufacturer's maintenance response speed and spare parts supply

4. On-site testing: It is best to test with actual production materials

GET IN TOUCH WITH US