How to slove the problem of blockage on a wood pellet machine?

First, let's finger out why caused Jam to the pellet mill.

There are several reasons as follows

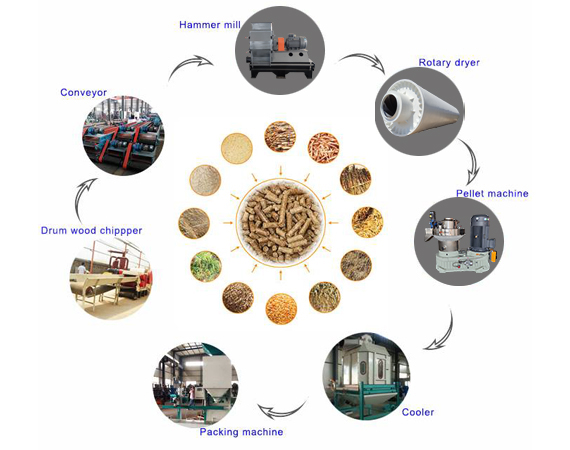

1. Wrong compression ratio of Die adopted in the biomass pellet machine.

2. Too fast for feeding.

3. High Humidity raw materails wihout any treatment.

4. Spare Part wearing too much.

5. Maintenance is not timely.

6. No wash and clean Ring Die for longer downtime.

Some Methods and suggestions for you to fix the wood pellet machine when any blocking.

1. replace the ring die with appropriate compression ratio.

2. adjustment the feeding rate, carefully observe the current of the electric control cabinet.

3. Reduce the moisture of raw materials by drying machine or drying in the sun.

4. Replace the bad condition of wearing parts. Each time when you change the ring die, better to replace new roller skins at the same time.

5. Do Regular maintenance. Strictly implement according to the user manual.

6. Wash the Die by mixture of wood sawdust with waste engine oil for each shift when you open and turn down the mill.

Pay more attention to the safety operation and ensure the smoothly running. If any problems for installation, repare or mainte the pellet mill, please contact YuFChina for technical support.

GET IN TOUCH WITH US