I want to produce pellets, what equipment do I need?

Simple line need only a pellet mill with feeding and discharge conveyor, that's all.

Only assuming the points as follows

* you already have qualified raw materials with suitable moisture & sizes for granulation.

* the required output below 2 tons

* not need packaging the pellet

* short storage period for the finished pellet.

But this is the first choice for newcomers who are just entering the industry.

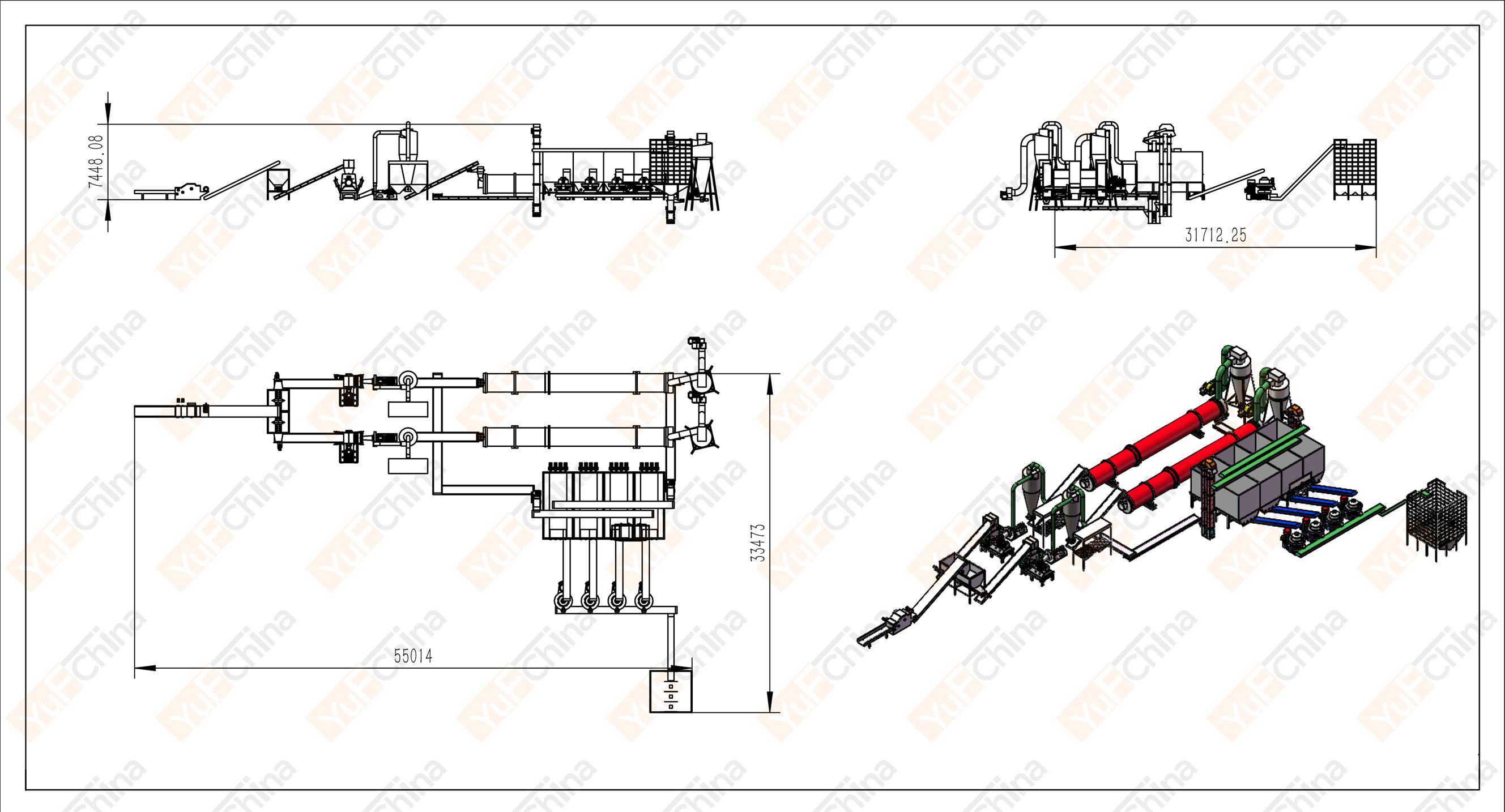

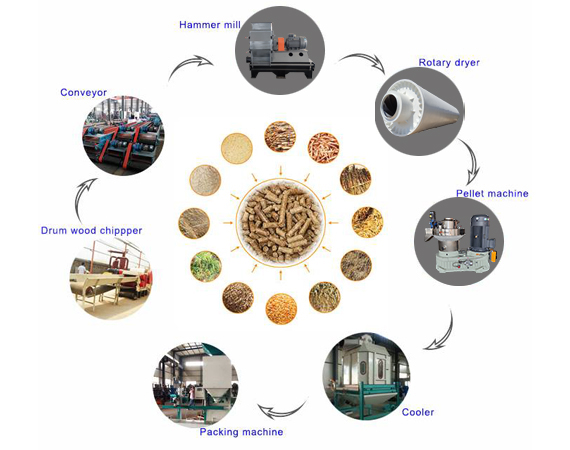

Generally, a complete line includes with Crusher, Hammer Mill, Dryer, Mixer, Pellet Machine, Cooler, Packing machine.

All those sections before the pellet mill are only for pretreatment of raw materials, so as to receive qualified raw materials with certain humidity and sizes for pelletizing.

Do I need a crusher or breaker?

Branches, logs, wooden pallets, wood stump, tree roots, bamboo, etc. need a crusher before the hammer mill.

How to choose the Crusher by different types? like comprehensive crusher, drum chipper, disc chipper, disc crusher, shredder, wood chipper, chain crusher, etc.

It depend on the type and size of your raw materials.

For example, palm fruit bunches (EFB) are processed with a shredder. The agglomerated cow dung needs a chain crusher, and the bundled straw and straw should use a disc crusher.

And the log can choose a comprehensive crusher or a drum chipper depending on the diameter. Building formwork requires a nail breaker, etc.

Before the crusher, do I need anything else?

It depends.

* A debarker machine needed to removing the barks, which to increase the pellet quality and reduce ash content for pellet.

* A log spitter will have if the wood Logs are too large, what will reduce the crusher sizes and input cost for machinery. As the Log Splitter cheaper cost.

* High Humidity mateirals need a screw press extruder for high humidity materials like Cow dung, etc.

Is it necessary to install the hammer mill?

After crusher, normally we need a hammer mill to process the wood chips into sawdust or particle between 3-8mm.

Of course you do not need a hammer mill or crusher, if the raw materials already with the right particle size.

The most popular type for hammer mill is divided into a multi-functional hammer mill and a high efficiency hammer mills. Different names are only for different feeding directions.

I saw some plant, they adopt primary and secondary crushing system, why?

In actural running site, most of the lines adopt one hammer mill system,

Most of the production lines only use one crushing process.

But for medium and large scale production lines, you may considering two stages of crushing process in the cases as

* raw materials with high humidity.

* continuous running with high capacity plant

Primary hammer mill for coarse pulverizing before the drying section. And the secondary hammer mill for finely powdered after the dryer machine. Sieve mesh sizes will be different for installation.

This aim to reduce the pressure of dryer's capacity and power consumption, and makes the line smoother & stable to keep good quality materials to be granulated.

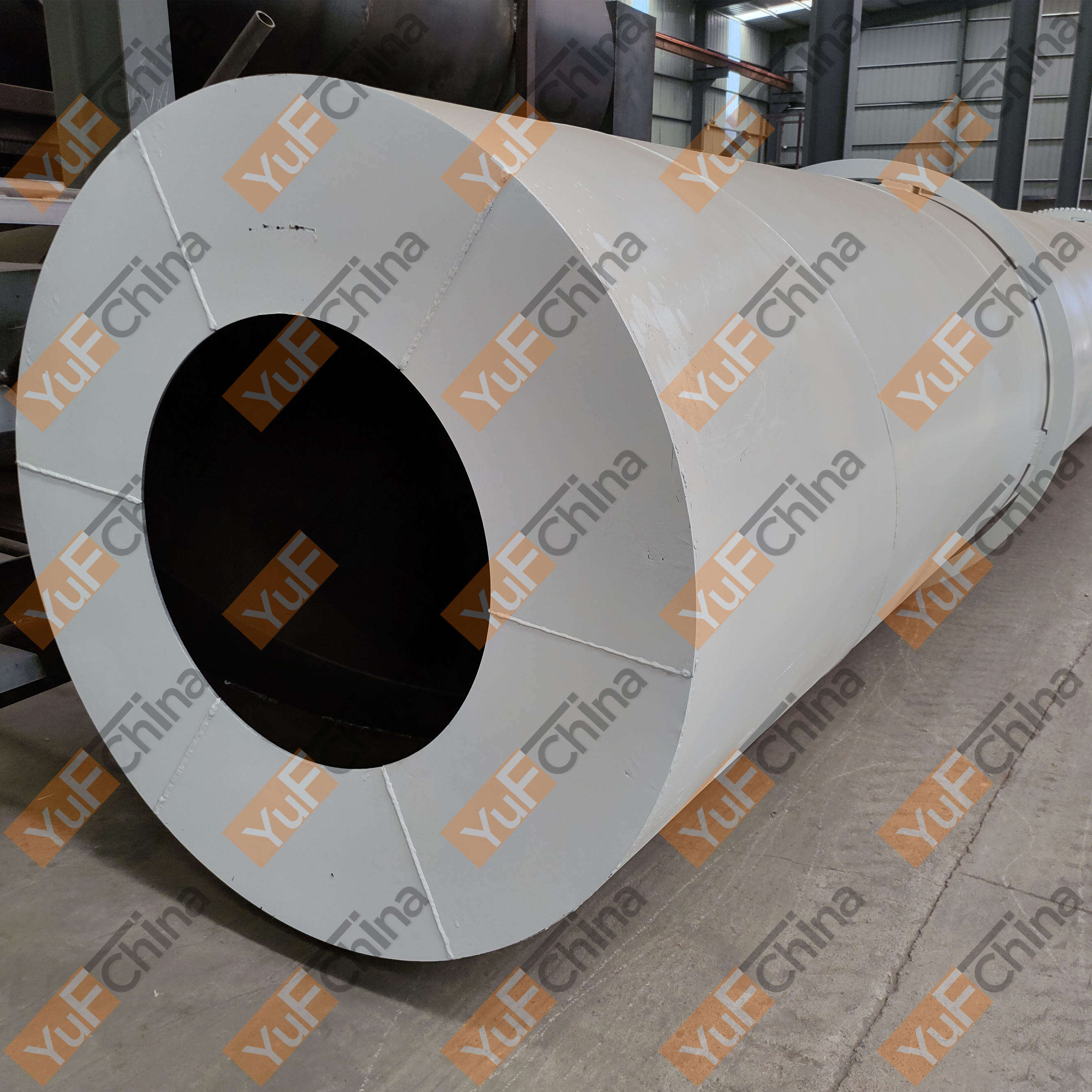

When I need a dryer machine?

If material moisture more than 20%, and you can't guarantee the right moisture by natural drying due to conditions or output, you need a drying machine.

Too much models of drying equipment to choose, like rotary drum dryer, three-cylinder dryer, round-pot intermittent dryer, vacuum dryer, airflow dryer.

We can help you to make the choice by factors such as raw material size, properties, moisture content, output, occupied limited, and capital budget.

What is the function of a mixer in the pellet plant?

Most regular production lines do not adopt the mixing machine.

But do you want to produce high-quality pellets, with the grade European eNplus A1 Level?

Undoubtedly, you need a mixer machine to achieve it.

To control the calorific value, moisture, sulfur & ash content, bulk density, of the wood pellet, mixer is necessay to adopt in addition to the qualified raw materials, pellet machines and running condition of the plant. In this way you can produce higher standard pellets according to chemical and biological characteristics.

What is the price for a pellet machine?

Years past from beginning with a flat die pellet machine, horizontal ring die pellet machine to a vertical ring die pellet machine.

Until today, the eighth generation vertical ring die pellet machine dominate the market for this industry.

Equipment performance & accuracy are optimizd by technology advancement, What makes today's pellet mill have a wider range of acceptance of materials type and moisture.

In the past, we should keep moisture between 8 and 13% for granulation. Now less than 20% moisture we can help you to make high-quality pellets, this not only reduces the investment and reduce energy consumption of drying equipment, but also makes the production more smooth and diverse.

Therefore, the cost of the pellet machine is important

But what is more important than the cost? Let's focus more on the following tips

* how to make the production smoother

* make more ideal production capacity

* keep reasonable energy consumption

* strive for better market for the finished product

This is the goal and direction we have been working hard for you.

Do pellets need a cooler and packaging?

It depends on the application for the finished product, market standards and storage period.

* If the pellets are self-consumed or consumed in a short period of time, the small production line may not need a cooling machine to reduce investment.

* Medium-sized production lines can choose reversible coolers, simple cooling bins, or mesh belt cooling conveyors.

* For large-scale production lines, we strongly recommend the use of reversible coolers.

To your market requirement, you can also choose a smaller bagging machine, single / double bucket packaging machine, tons bagging machine, etc.

So whether you want to invest in a large, medium or small pellet plant, the solution is flexible and adjustable.

GET IN TOUCH WITH US