Six Important Factors When Choosing the Raw Materials of Wood Pellet

Biomass pellet, also called as wood pellet, the main raw materials was the sawdust, shavings, bark, sanding powder, waste wood, branches and sapwood produced by wood processing and wood-based panel production, every kinds of straw produced after harvesting crops, and other types of combustible biomass. It was used for combustion, barbecue and fireplace heating.The combustion efficiency is over 80%(over 60% of the efficiency of ordinary coal combustion), the combustion is high and produces less sulfur dioxide, ammonia nitrogen compounds and dust.So, what do you need to notice when choosing the raw material of wood pellet? YuFChina prepared six main factors for you:

Is different type of wood chips can be added together?

The so called pure wood chips, was not means cannot add other types of sawdust.Different types of wood chips, like shaving sawdust, mahogany, poplar and the waste of the furniture factory is all feasible to make wood pellet. More broadly, like crop straw,peanut shells also can be used as the raw material of wood pellet, just the pellet should be called straw pellets, instead of sawdust pellets.

What should to do with the mildew of the raw materials?

If the raw material is mildewed, the color will turn to black,the cellulose in the wood chips is decomposed by microorganisms and cannot be pressed into qualified pellets.If want to use the mildew materials,we recommend you to add more than 50% of the fresh wood chips to mix,and then produce, this can guarantee the quality of the pellets.

The size of the crushed material

The materials like sawdust, wood branches must be pulverized by hammer mill before granulation, the size of the pulverized materials was decided by the expect diameter of the pellet and the pore size of the granule mold. If the pulverized materials is too large or too small, it would affect the capacity and even caused no discharge of the pellet machine.

The requirement to the moisture is very strict

The pellet machine have high demanding to the moisture of the materials, no matter which kind of sawdust, the moisture should be kept at 14%-20%. It is too dry to form and easy to loosen if the moisture is large.

The adhesion of the raw material

The raw material itself must have adhesion, without adhesion, the pellet either not easy to form or too loose and easy to broken. Therefore, if the material without adhesion can be pressed into pellets, there must have some problems with the raw material, or was fermented or was added the adhesive or something like that.

Adding adhesive

The sawdust is enough to make wood pellets, neednвАЩt adding adhesives, the sawdust have adhesion as it is an crude fibers material.After the compression of the pellet machine, it can be formed naturally, and it will be very strong, as the pressure of the pellet machine is very high.

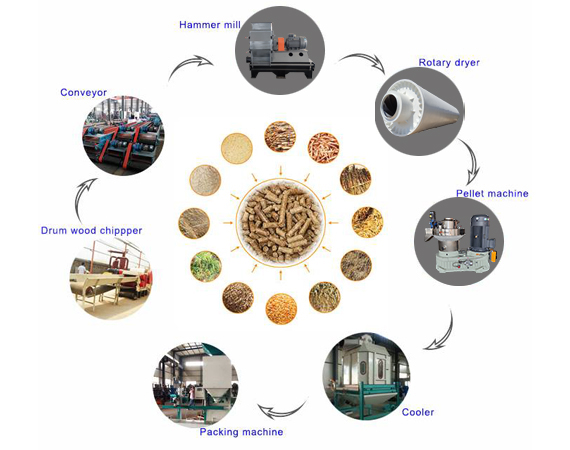

YuFChina can provide you with different purchase guidance of the Biomass pellet equipment, we can customized your own pellet production line according to your requirements. We have many years experience in exporting the biomass pellet production equipment, we have completed after-sales service, our engineers available to offer installation guidance in your site, resolve all of your worries.

GET IN TOUCH WITH US