Why and how to make biomass pellet by rice husk?

1. Why we make rice husk pellet?

- As a readily available and low cost raw materials, rice husk is a by-product of a large number from farmland and rice processing factories. And it is easy to obtain with a relatively lower cost for pellet making.

- Heating value and specification: Rice husk particles have a economic calorific value and can be used as raw materials to make biomass fuel. It has less emissions during the combustion process and has higher combustion efficiency.

- Application: Rice husk pellets can be used in heating, hot water supply, power generation and other industries, such as animal feed and soil improver.

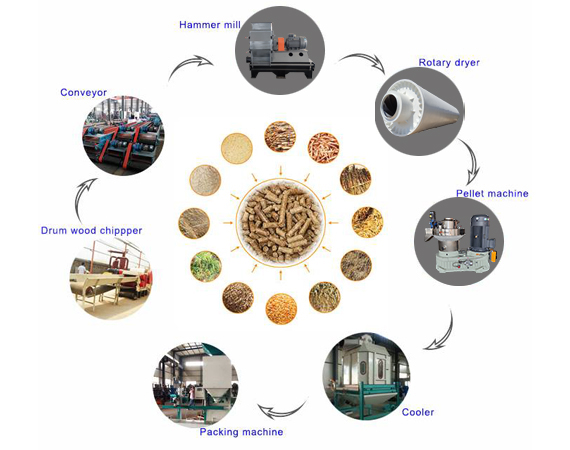

2. How to make fuel pellet by rice husk?

- Sieve: Sieving the rice husks to remove impurities such as strings, small stones and metals etc.

- Granulate: 100% rice husk can be directly granulated into biomass pellet, compared with other raw materials such as wood, it can save a lot of cost in the raw materials treatment process, such as crushing and drying. This helps the investors save money.

- Cooler: When discharge from the pllet mill, the temperature for pellets is high, so the pellet cooler can effectively reduce the temperature of pellets for longer period stored.

- Package machine: normally 20-50kg per bag to pack the rice husk pellet into bags, which is convenient for storage and transportation.

3. Brief introduction of the ring die pellet machine

For Rice Husk Pellet Making, Ring Die Pellet Mill is recommend with its high efficiency, stability and flexibility.

The percentage for rice husk as raw materails, can be adjustment by your exact case. Rice Huck pellets have more advantages over fossil fuels and bulky rice husk as fuel.

It is a good option if you have a steady source of rice husk and want to profit from it.

If you have questions about pellet production or biomass business or are interested in making related investments, please fill out the form below to send us an inquiry. We will do our best to help you.

GET IN TOUCH WITH US