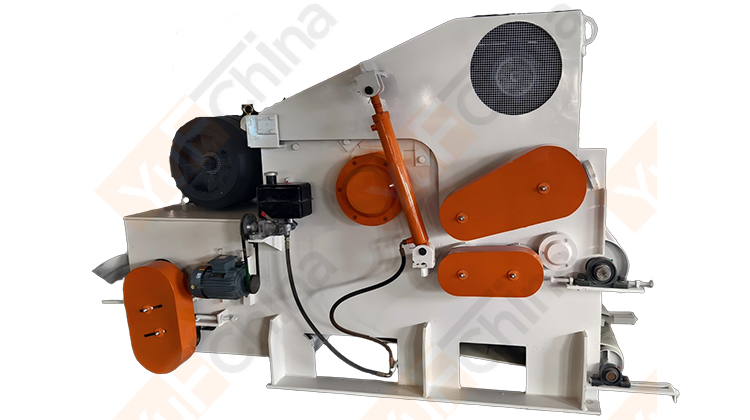

Professional 90 KW 218 Drum Chipper for Large-Scale Wood Waste Processing

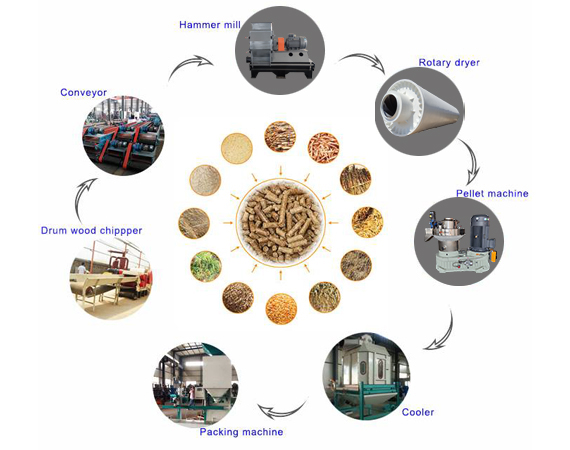

Raw Material of Drum Wood Chipper

A commercial wood chipper is designed to process large quantities of timber materials, including logs, branches, and various forestry residues. This heavy-duty equipment efficiently handles wooden harvesting residues (trunks, branches, etc.) and wood processing residues (bark, slats, logging waste, scrap planks, etc.). The final product produced by this industrial wood chipper consists of uniform 3-5cm wood chips, suitable for biomass energy, mulch, or pulp production.

Advantage of Industrial Wood Chipper

* Strong body of Industrial Drum Wood Chipper Machine

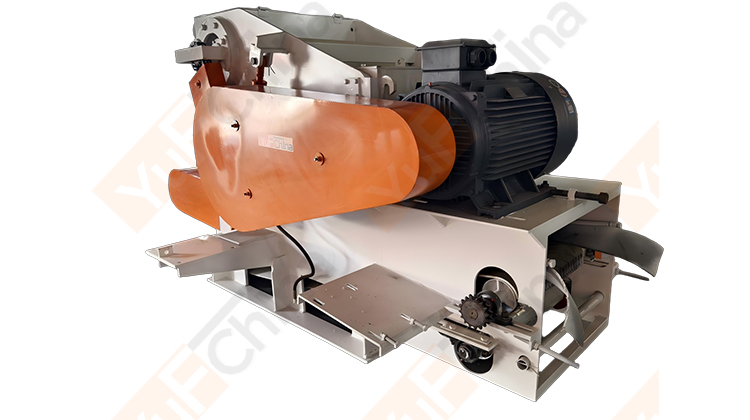

* Two Feeding System adopt to choose as blet conveyor or chain conveyor

* Feed roller adopts 45# Mn steel, with strong abrasion and precise bite force, the strength and performance good.

* 65# manganese steel, anti-wearing, prolonging service life and available for hard wood.

* Blade thickness 20mm, with 1mm thikness. 4-6 months lifetime for each grinding.

Technical Parameter

| Model | GX218 |

|---|---|

| Rotor diameter (mm) | 800 |

| Blade quantity (piece) | 3 |

| Input size (mm) | 680 x 310 |

| Blade rotational speed (rpm) | 650 |

| Rate of feeding (m/min) | 35-38 |

| Max material diameter (mm) | 300 |

| Capacity (tph) | 6-10 |

| Main power (kw) | 90/110 |

| Feeding motor (kw) | 5.5+4 |

| Discharging motor (kw) | 4 |

| Oil pump motor (kw) | 3 |

| Feeding conveyor length (mm) | 6000 |

| Discharge conveyor length (mm) | 10000 |

| Weight (t) | 7 |

Drum Chipper Machine Models

| Model | Max feed size (mm) | Capacity (t/h) | Weight (T) |

|---|---|---|---|

| 216 | 200 | 3-5 | 4.5 |

| 218 | 300 | 6-10 | 7 |

| 2113 | 350 | 15-25 | 11.84 |

GET IN TOUCH WITH US