how to make wood pellets

Wood pellets, as a kind of cylindrical pellets which made by hardwood, mixture of wood, rice husk, palm fruit bunches and other raw materials. As a renewable Green Energy Resources, the wood pellets burns efficiently without pollution,and produces stable heat over a long period of time.

With the rising price for natural gas and petrol, people shows interest in the biomass fuel. You can save 50% cost when adopting the wood pellets as fuel.

In the United States, wood pellets already become a widely accepted fuel for heating residential and commercial properties during the winter. Apart from this, individuals use wood pellets for cooking, industrial boilers and power plants.

In several European countries, combined heat and power plants use wood pellets to drive turbines for electricity generating.

In this article, letвҖҷs learn how to make biomass pellets (wood pellets)

The chemical ingredients of wood pellets are cellulose, hemi-cellulose, lignin and extracts. Lignin acts as a binder between cellulose. Therefore, no need any chemical binder or additives to make wood pellet, because it is only the physical process. After pelletizing, the pellet density will become to 800-1300kg/m3пјҢ which will extend the burning time.

Raw materials for pellet making

There are many kinds of raw materials for pellet making, such as hardwood, wood mixture, softwood, waste template, rice husk, peanut shell, palm fruit bunches, alfalfa, etc. Different raw materials require The production design will be different when treated with different raw material, which will directly affect the cost of the entire production line. For example, If you adopt wood logs, wood crusher, chipper machine, hammer mill, dryer, etc., and if you adopt wood chips directly, we can remove the wood crusher and wood chipper, can a dryer will be decide according to the humidity of raw materials. The suitable moisture for the raw materials will save a lot for the equipment cost as well as the energy consumption. Definitely it will be decide according to your local materials available.

Sections for pellet making

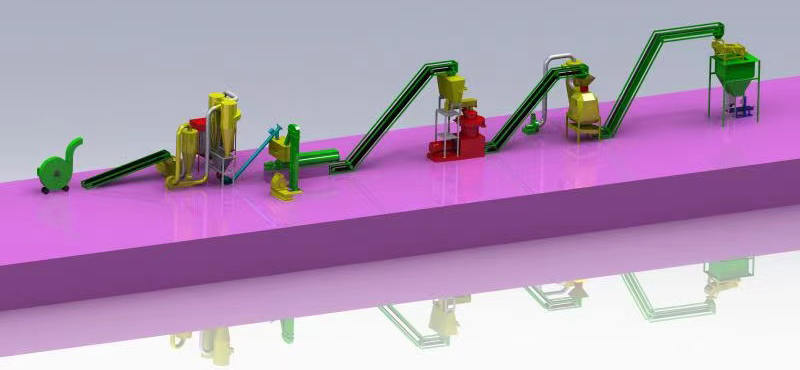

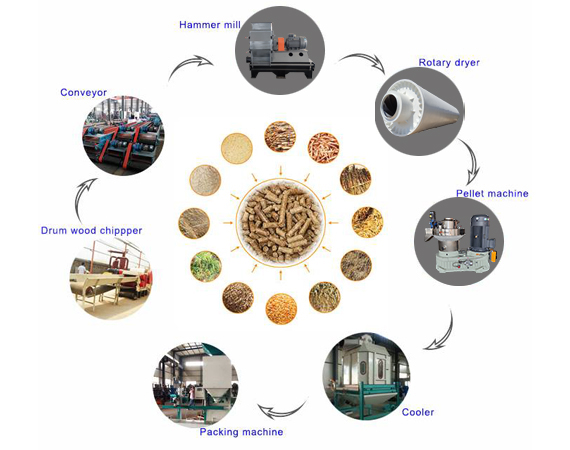

The whole pellet production line is set up by the wood pellet machine, drum chipper, hammer mill, dryer, cooling machine and packaging machine, etc. The corresponding production process is configured according to the different raw materials. The production process includes: chipping, drying, crushing, granulating, screening, cooling, packaging, etc.

Details as follows:

1. Wood Chipping Section

As an important part of the production for wood pellets, Wood chipper is to cut large raw materials such as logs, branches, waste templates and other raw materials into 3-5cm wood chips for the next step of processing, Different types of wood crusher can be selected to complete the job The wood treatment equipment include, disc chipper, drum chipper, comprehensive hydraulic wood crusher, branch crushers, etc.

2. Drying Section

The ideal moisture for making wood pellets is between 8 to 12%. Within this moisture range we will make pellet without the drying, otherwise we need a dryer. The dryers type include: airflow dryer, rotary drum dryer, three-cylinder dryer, etc.

3. Wood Crushing Section

The size of the raw material for making wood pellets is between 3 to 6mm, so it is necessary to use a hammer mill to get the required sizes. The sizes will be different according to the types and raw materials and pellet diameter needed.

4. Pellet Making

The granulator is the key part for the whole process. The qualified sawdust will be feed into the hopper of pellet mill, and the pellet machine presses the wood sawdust through the rotating roller driven by the electric motor. Wood pellets will be extruded from the ring die holes and cut by rotary blades until reaching the preset length.

5. Wood Pellet Cooling

After wood pellet making, for commercial usage pellet, we need to cooling the pellet immediately. Cooling freshly produced pellets prevent pellet resurgence and keep high-quality pellets and extend storage time. You can use a counter-flow cooler to cool wood pellets.

6. Pellet Screening

Screen machine will send the qualified pellet to the packaging machine for market sales, and the unqualified will be crushed by the pulverizer and re-granulated to avoid material waste.

7. Wood Pellet Packing Section

Packing the cooled pellets in moisture-proof bags or containers also helps prevent them from absorbing moisture from the environment.

The above information based on on how to make wood pellets, which is more applicable to commercial biomass pellet factories. If you want to make wood pellets at home on a small scale for your own use, the process will be much simpler and easier. You only need to collect the prepared dry wood chips and send them into the flat die pellet machine through the hopper to get wood pellets directly.

The production process is a not fixed design, and the most reasonable solution can be designed and supplied according to your requirement.

Some tips for storing the wood pellets

The demand for wood pellets naturally decreases during the summer. As a result, you must establish a suitable storage place for wood pellets.

Always store your pellets in a dry place. They should not catch fungus that flourishes in wet conditions.

Remember, moist pellets will not burn appropriately and make excessive smoke while burning.

Give your pellets a consistent temperature during the storage.

Check out if you need to control humidity in the storage area. The low humidity environment is ideal for pellet storage.

Keep your wood pellets away from all water sources.

Similarly, avoid heat sources. As wood pellets are highly flammable, do not store them near any heat source, such as a fire table, heater, furnace, etc.

Always raise your wood pallets off the ground as the ground could be hotter and colder than the temperature.

Let us find out why wood pellets are an ideal choice in modern times.

Wood pellets are affordable fuel for home heating than oil, gas, and standard electric heaters.

They produce consistent heat for a long period.

They are carbon neutral and release less carbon dioxide to the environment than burning logs.

They also contribute to the conservation of landfill resources since you utilize a lot of wood and other leftovers as raw material.

Since they burn with high efficiency, they release fewer pollutants.

Because wood pellets and their raw materials are acquired and produced locally, it supports employment and brings business possibilities to local communities.

GET IN TOUCH WITH US