The difference between vertical ring die pellet machine and flat die pellet machine

The difference between vertical ring die pellet machine and flat die pellet machine

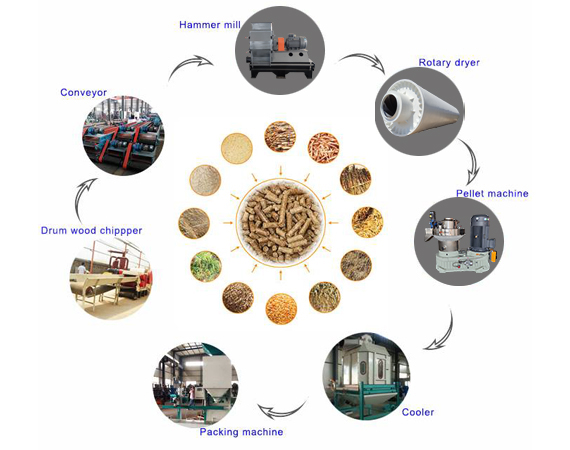

Vertical ring die pellet machine and flat die pellet machine are two common biomass pellet machines, both of which can press agricultural and forestry waste, sawdust, straw and other raw materials into pellets for fuel or feed. However, there are some differences between them, mainly in the following aspects:

1. Volume and price. The output of the vertical ring die pellet machine is generally between 0.8-20 tons per hour, much higher than the 60-1200 kg/hour of the flat die pellet machine. Therefore, the price of the vertical ring die pellet machine is much higher than that of the flat die pellet machine, which is suitable for large-scale production needs.

2. Structure and working principle. The main components of the vertical ring die granulator are a vertical ring die and two pressure rollers. The material enters the pressing chamber from above and is squeezed by the pressure rollers to form granules through the die holes. The main components of the flat die granulator are a horizontally placed disc-shaped mold and a pressing roller. The material enters the pressing chamber from the center, is pushed by the pressing roller and rotates along the surface of the mold, and forms granules through the holes of the mold.

3. Scope of application and easy maintenance. The vertical ring die pellet machine is specially designed for raw materials such as straw and wood chips with light specific gravity, and the moisture requirement for raw materials is relatively low, generally between 10-15%. The flat die granulator is suitable for various raw materials, and the moisture requirement of raw materials is relatively high, generally between 15-25%.

To sum up, the vertical ring die pellet machine and the flat die pellet machine have their own advantages and disadvantages, and users should choose the appropriate model according to their actual situation.

GET IN TOUCH WITH US