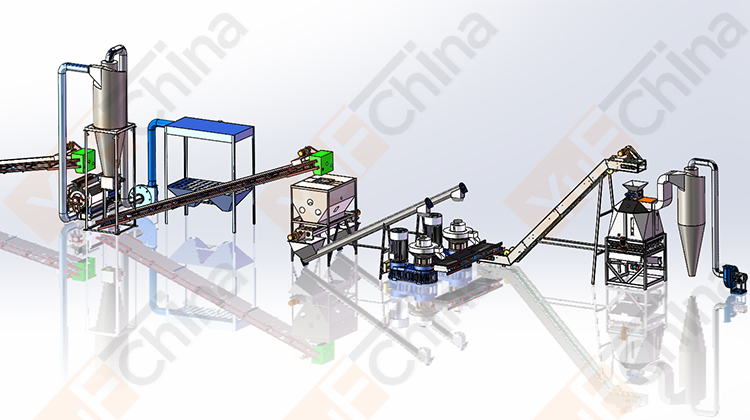

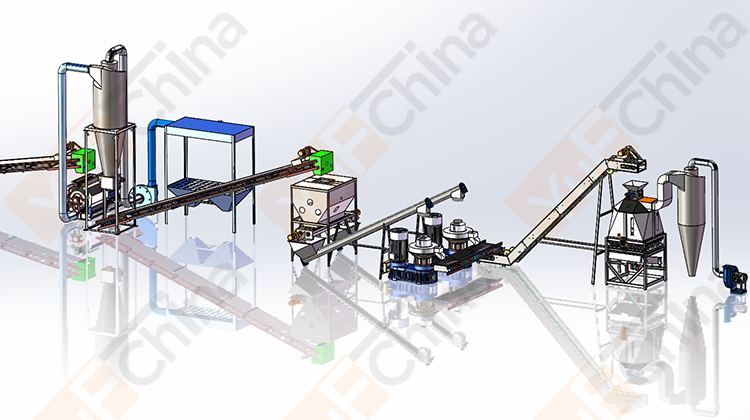

Biomass Pellet Production Line

The complete biomass pellet production line is designed for industrial production. It can produce biomass pellets from various agricultural and forestry wastes, and the output can be designed to be 1 ton to 20 tons per hour. The finished biomass pellets are widely used in industrial boilers, heating of large power plants and household use to alleviate the energy crisis and meet environmental protection requirements.

YUFCHINA Biomass Pellet Production Line, this pellet production line comes with everything you need to process just about any biomass and wood. It can be used to produce pellets of all kinds, allowing you to speed up your production process and improve your bottom line.

I want to produce pellets, what equipment do I need?

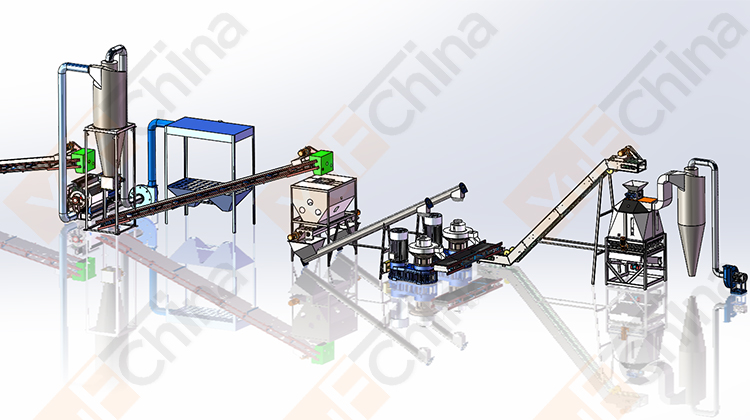

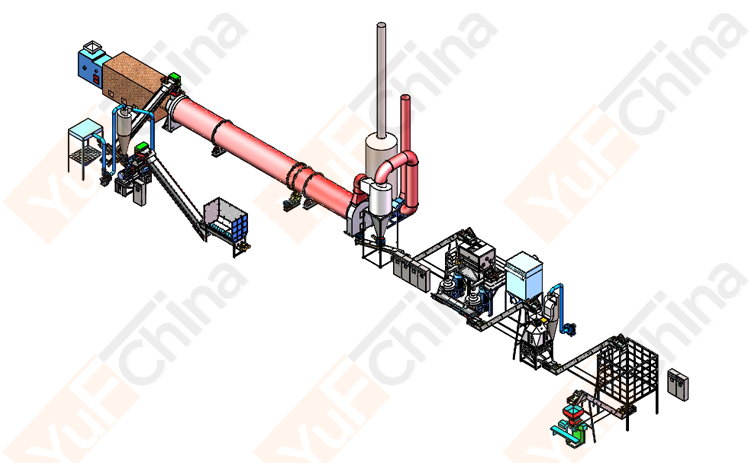

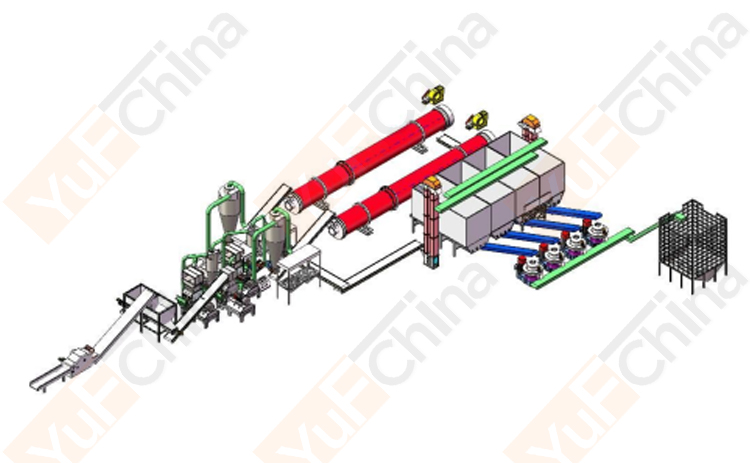

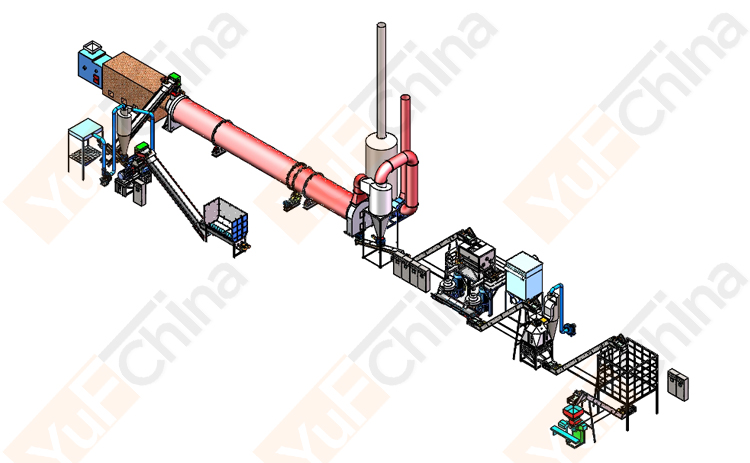

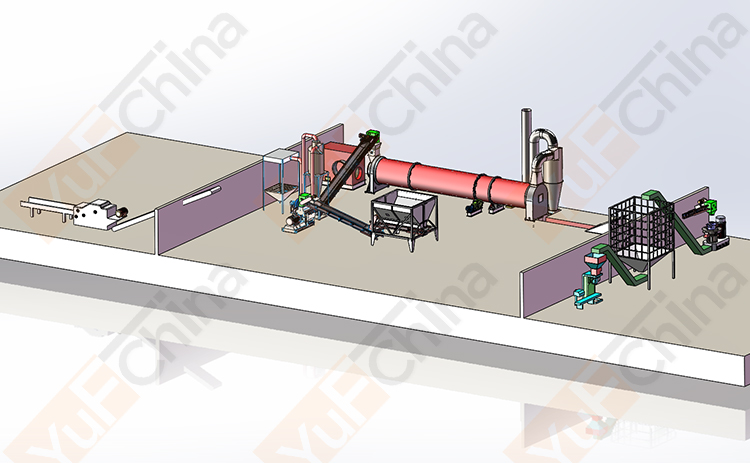

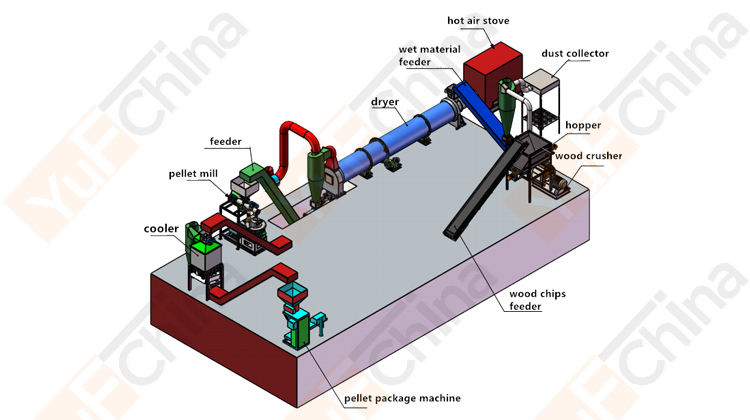

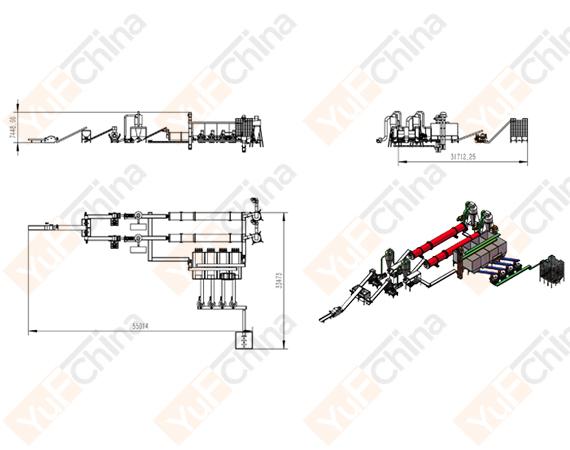

The whole pellet production line is set up by the wood pellet machine, drum chipper, hammer mill, dryer, cooling machine and packaging machine, etc. The corresponding production process is configured according to the different raw materials. The production process includes: chipping, crushing, drying, pelletizing, screening, cooling, packaging, etc.

Pellet production can utilize a wide range of raw materials, including hardwood, mixed wood, softwood, waste templates, rice husks, peanut shells, palm fruit bunches, and alfalfa, among others. The processing of different raw materials requires tailored production designs, which directly impact the overall cost of the production line.

For instance, if wood logs are used as the feedstock, the necessary equipment typically includes a wood crusher, wood chipper, hammer mill, dryer, pellet mill, pellet cooler, and pellet packing machine. In contrast, when starting with wood chips, the wood crusher and chipper can be omitted from the setup. The need for a sawdust dryer, meanwhile, depends on the moisture content of the raw materials. Maintaining the raw materials at an optimal moisture level not only reduces equipment costs significantly but also lowers energy consumption. This underscores the importance of assessing local material availability when planning the production line.

Whether you intend to invest in a large, medium, or small-scale pellet plant, the solution can be flexibly adjusted to suit your specific needs and raw material conditions.

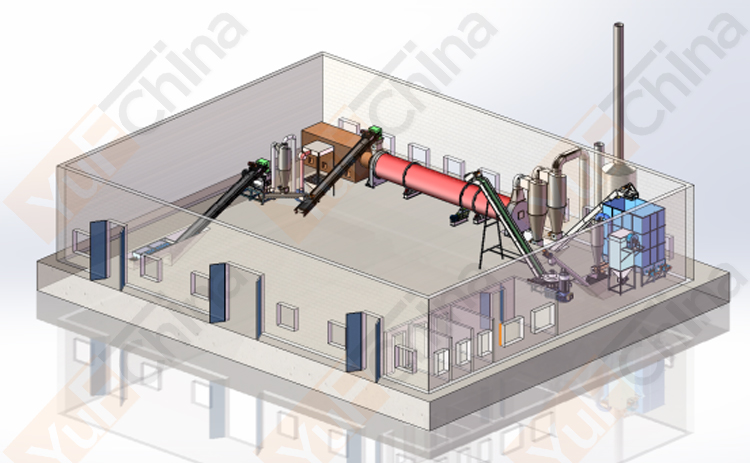

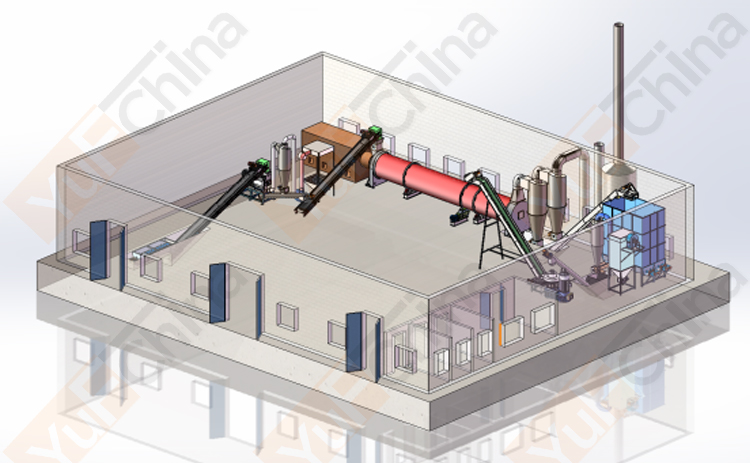

How much space of workshop do I need for set up the biomass pellet plant?

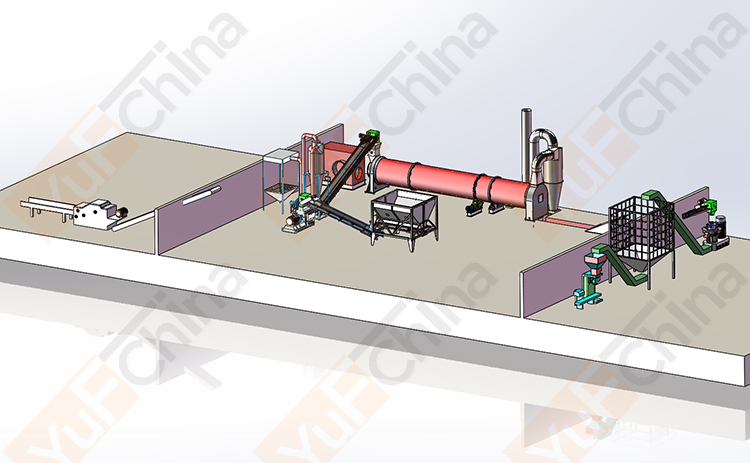

Small production line: For small-scale biomass pellet production lines, the recommended floor space is usually around 500-1000 square meters. This scale is suitable for start-ups or small production needs, the equipment is relatively simple, and the output is usually 1-2 tons/hour.

Medium-sized production line: Medium-sized production lines generally require a plant of 1000-3000 square meters, which can support a production capacity of 3-5 tons/hour.

Large-scale production line: Large-scale biomass pellet plants usually require a plant of more than 3000 square meters, which is suitable for large-scale production, with an output of more than 5 tons/hour, involving more equipment and process flows.

1. Locates the market and profit margin for the project.

2. Feasibility analysis, like raw materials source, production cost, geology, climate, etc.

3. Factory Conditions: The workshop must have sufficient space and appropriate infrastructure to accommodate the production equipment.

4. Power Tranformer Implement: Ensure that there is ample electricity supply nearby, including access to high-capacity transformers necessary for the operation of the production line.

5. Raw Material Availability:

- Source and Stability: Consider the sources of raw materials and their reliability to guarantee uninterrupted production.

- Cost Impact: The type of raw materials and their procurement costs will directly affect both the initial investment and ongoing operational expenses of the production line.

FAQ

Q: How to produce good quality wood pellet?

A: There are 3 points.

*reasonable process design & realiable pellet machine & suitable compress ratio of die

*clean and high quality raw materials

*clean and good condition for the running site.

Q: What is the diameter of pellet is popular in Europe, Japan, Korea, etc?

A: 6 mm - Europe market; 6-10 mm for Japan market; 8 mm for India,and Southeast Asia countries market.

Q: I have options of different size of pellet, adopt one pellet mill is okay?

A: Yes, we only need to change the ring die.

Q: I have different source and kinds of raw materials, only one pellet mill is workable?

A: Yes, the same pellet mill is ok, we only need to change the ring die.

Q: I don't know the moisture of my raw materials.

A: You need a humidity tester or the moisture tester. It is very cheap and convenient.

Q: Kindly explain whether we should add any chemical binder to the feed material in pelletizing process?

A: When making wood pellets, we do not need any binder or additive, because the additives will influence quality and combustion of the pellet.

Q: What raw materials can be used to produce wood pellet?

A: Soft wood, hardwood, wood log, teak wood, sugar palm, cocoa shell, acacia species, rice husk, groundnut shell, rubber wood, pineapple lattice, rosewood, Oak, nanmu, hemlock, rutwood, cotton stalk, pine wood, EFB / empty fruit branch, rice husk, coconut shell, cashew shell, olive shell, birch wood, straw, shrub, pine needle, coniferous or evergreen arbor, forest shrubs, bagasse, fir tree, firewood, bamboo.

Q: The pellet mill can work 24 hrs per day?

A: Yes, indeed 24 hrs running no problem, normal maintenance is necessary.

Q: How to making pellets if raw materials have low humidity (insufficient for good pressing).

A: If the humidity of the raw material is relatively low, you can add a sprayer / conditional / blender to spray water of the raw material.

Q: When do I need a dryer

A: If high moisture of raw material, better to adopt a dryer to guarantee the good condition of the wood pellet mill. Of course if very small capacity plant, we will got for fully natural drying or simple drying solution.

Q: What is the moisture of fresh natural forest after cutting?

A: Fresh cut is about 60-80%. But after transportation and placed for a while, the moisture will be 40-55%, and is different according to the external environmental factors.

Q: What is the recommend compression ratio of the die?

A: The compression ratio can be determined according to the user's raw materials.

Q: If the machine stop to run or have problems, what can I do?

A: First please do not worry, after-sales service 24 hrs on line to help you. Almost all problems will be settled by video call, telephone, email, etc. If can not, we will fast send engineer to come to help you.

Q: What is the material for ring die? stainless steel or alloy steel?

What is the brand of bearing?

A: Standard is Alloy steel, Stainless Steel is optional to choose.

SKF International Brand Bearing adopted.

Q: What factors may influence the quality of the pellet?

A: type and quality of raw materials, moisture of material when pellet pressing, compression ratio of ring die , designed process, working condition, etc

Q: The price is high, how can I reduce the cost?

A: The production line is divided into high, medium and low configurations, and some sections can be simplified or delete, then we can reduce the investment. For example, the cooling and packing sections are optional by your choice.

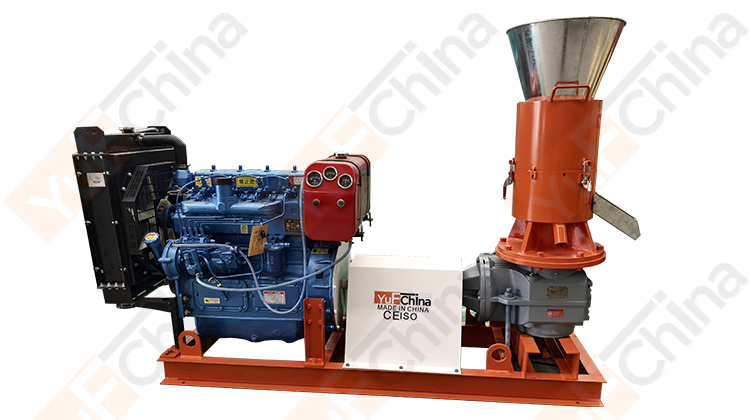

Q: Do you have CE certificates and ISO for the pellet mill?

A: Yes, YuFChina equipment focus on the international market.

GET IN TOUCH WITH US