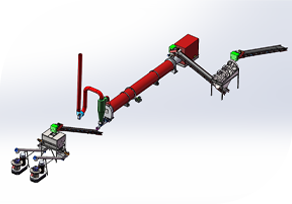

Full Automatic Biomass Pellet Machine

Locate the market

Requirement Discussion

Make Design

Design Confirmation

Production & Inspection

Installation & Debug

Product Parameters

| Model | Power(kw) | Capacity(t/h) | Weight(t) |

|---|---|---|---|

| XGJ460 | 55 | 0.6-0.8 | 3 |

| XGJ560A | 90 | 1.2-1.5 | 4.2 |

| XGJ560B | 110 | 1.4-1.7 | 4.5 |

| XGJ560C | 132 | 1.7-2.5 | 5 |

| XGJ700 | 160 | 2-3 | 8.5 |

| XGJ850A | 220 | 2.5-3.5 | 12.6 |

| XGJ850B | 250 | 3-4 | 12.6 |

Product Features

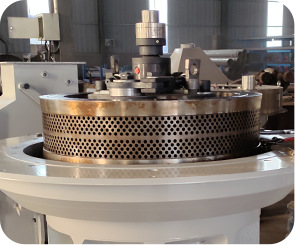

Double-layers Ring Die

Adopt double-layer ring die can extend the service period and reduce the long-term running cost.

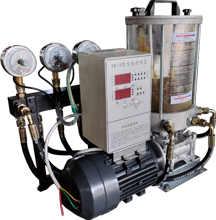

Automatic Lubricant Pump

Automatic lubrication for the key components of the machine, such as the pressure roller, feed plate, and the main bearing, reducing the difficulty of maintenance.

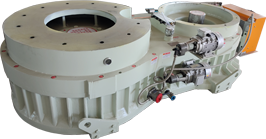

Advanced Gearbox

Improve transmission efficiency, reduce vibration and noise, and improve space utilization and heat dissipation performance.

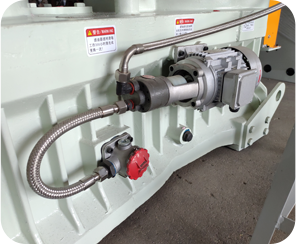

Circulating Oil Pump

Ensures uniform distribution of gear oil inside the reducer, thereby improving the equipment stability and reliability of the reducer.

Cooling Fan

Effectively reduce the temperature of the gear oil for the reducer.

Widely Application

Pellet Display

How To Make Money By Pellet Production

Location And Sizing The Workshop

Raw materials, transport, power, market competition, and space must be considered comprehensively. Reasonable size will reduce material transportation costs and improve production efficiency.

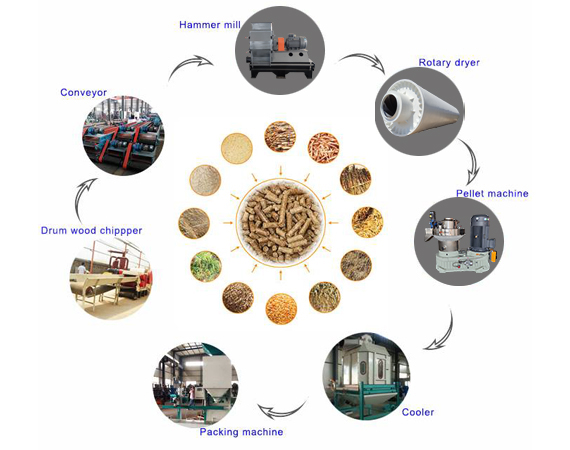

Flowchat Design

Design from pretreatment of raw material such as crushing, pelleting, drying, pelleting, cooling, etc., to ensure the rationality and continuity of the entire production process.

On-site Installation

Send professional technicians to install and debug the equipment on time.

Operation Optimization

Based on production data and feedback, continuously optimize to improve production efficiency and product quality.

FAQ

Payment methods

T/T (bank transfer), LC (letter of credit), T/T (international business transfer, which is relatively simple).

Choose the right machine, what we should considering?

Raw material, production capacity, pellet quality requirement, customs clearance cost, installation & easy maintenance.

How to handle the transportation and installation for the biomass pellet plant equipment?

Transportation: We cooperate with professional freight forwarders to handle customs clearance documents and procedures.

Installation: Provide on-site installation and commissioning services to ensure that the machine operates as expected. And provide video guidance services.

What is the reason for pellet mill producing bad quality pellet?

Moisture content (humidity of raw material), mold compression ratio (key factor for pellet quality), raw material purity (impurities affect pellet quality).

I have options of different size of pellet, use one pellet mill is okay?

Yes, only need to change the ring die.

What factors may influence the quality of the pellet?

Type and quality of raw materials, moisture when pressing, compression ratio of die, pellet mill wear condition.

The price is high, how can I reduce the cost?

The pellet mill is the core equipment. For example, the cooling and packing sections are optional; you can simplify or delete them to reduce investment.

GET IN TOUCH WITH US