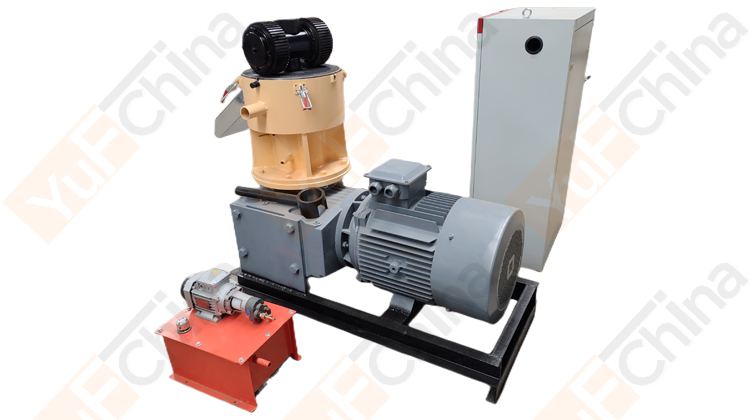

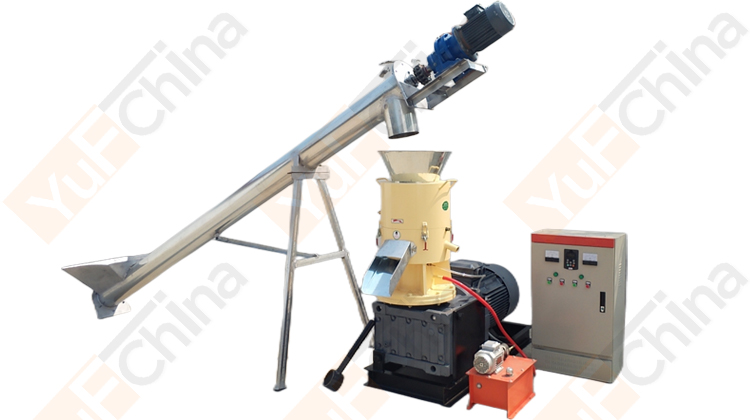

37KW 400 Cow Dung Pellet Mill

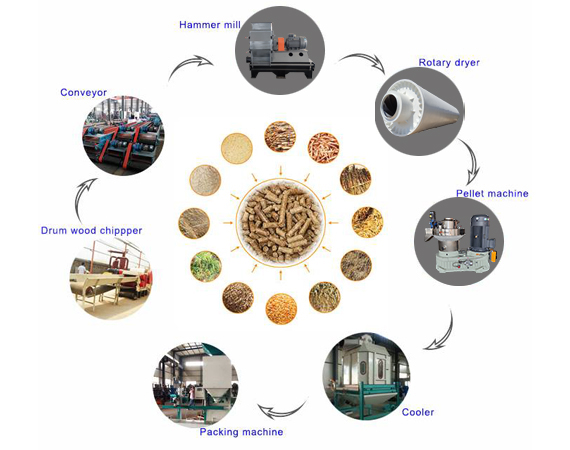

Flat die wood pellet machineis the use of crops, corn stalk, straw, straw, peanut shell, corn cob, cotton stalk, soybean stalk, rice husk, weeds, branches, leaves, sawdust, bark and other solid waste as raw materials, after crushing, pressure, densification, molding, become a small stick solid rest pellet fuel. Pellet fuel is made of wood chips and straw scales by pressing roller and flat die at room temperature. The density of raw materials is generally about 110-130kg/m3, and the particle density after molding is greater than 1100kg/m3. It is very convenient for transportation and storage, and its combustion performance is greatly improved.

Advantage

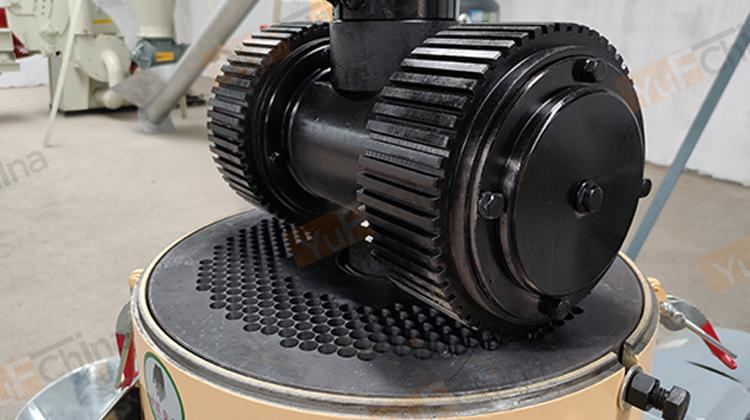

Thepress rollerandgrinding discof our flat die pellet mill are fabricated fromchromium-manganese steel, offering10 to 20 times higher wear resistancethan conventional steel afterhigh-temperature heat treatment and quenching. Thisdurable constructionensures extended service life, reducingmaintenance costsfor bothbiomass pelletingandindustrial material compressionapplications. The enhancedsurface hardnessandfatigue resistanceenable stableparticle density control, while theenergy-efficient designminimizes power consumption, making it ideal for small-scale to medium-sizedpellet production lines.

37KW 400 Flat Die wood pellet mill Technical Data

| Model | 400 |

|---|---|

| Power | 37kw |

| Output for wood or fiber | 400-500 kg/h |

| Die Size | 6-12mm |

| Machine Size | 1500*580*1440mm |

| Machine Weight | 1000kg |

Flat Die Wood Pellet Mill Technical Data

| Model | Power (kw) | Capacity for wood (kg/hr) |

|---|---|---|

| 200 | 7.5 | 80-100 |

| 260 | 15 | 100-200 |

| 300 | 22 | 200-300 |

| 350 | 30 | 300-400 |

| 400 | 37 | 400-500 |

| 450 | 45 | 500-600 |

| 450 | 55 | 600-800 |

| 560 | 75 | 800-1000 |

GET IN TOUCH WITH US