Why we need to grind and lubricate the Ring Die of pellet mill?

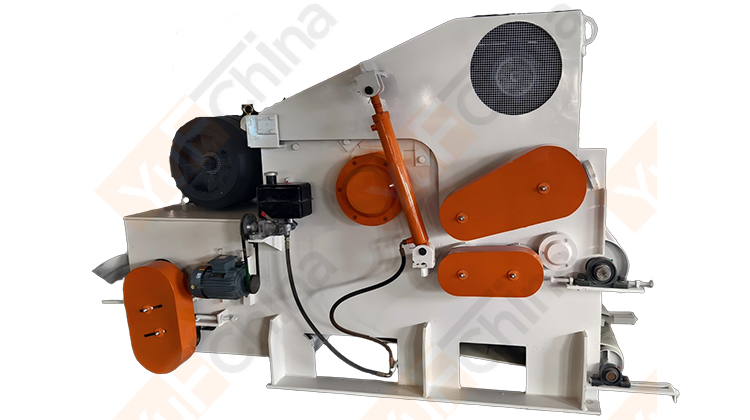

Wood sawdust pellet machine commonly used for producing wood pellet fuel, which compresses wood sawdust and other wooden materials into pellet column. That made significant contributions to energy utilization and environmental protection. So more and more pellet plant set up for production the biomass fuel pellet.

However, many people face problems when they run the pellet mill and producing wood pellet. For example, why and if we need to lubricate the ring die in production.

many people have questioned the need for grinding in the wood chip pellet machine. This article will address this question based on the reasons of eliminating burrs, preventing blockages, and the grinding process itself.

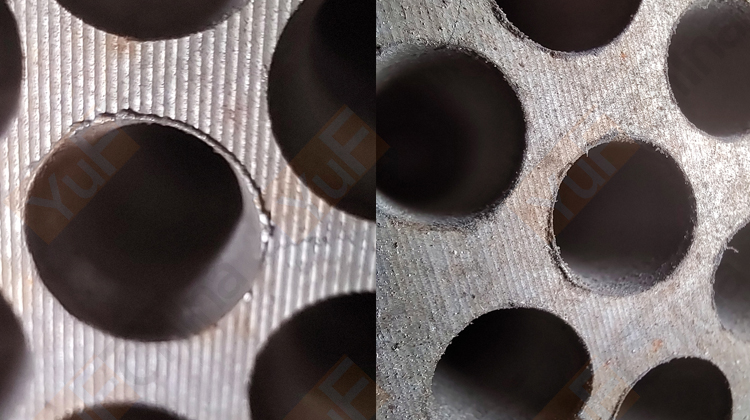

1. Eliminate Burrs - in the inner hole of the new Die:

During the running of sawdust pellet mill, the fiber materials are compressed in the pellet machine and formed into pellets through the die aperture. But There are some burrs in the inner hole of the new die, and these burrs will have a certain impact on the quality of the finished wood pellet fuel. By grinding the mold, all burrs in the inner hole of the die can be eliminated, which make its surface smoother, thereby to improve the quality of the wood pellet.

2. Preventing Blockages:

If you stop the machine for a long time, the sawdust remaining in the mold will block the mold holes once it turn on, which increase the workload of cleaning the mold. Through die grinding and oil lubrication, filling the mold with oil materials before shutting down the pellet mill can avoid clogging, improve production efficiency and improve the gloss of the finished pellet.

3. How to Grind and lubricate the Ring Die?

Mix sawdust with 30% sand, then add about 10% industrial machine oil. Before feeding please mix them uniformly, then manually put and press pellet in the wood pellet mill, repeat 5 to 6 times about 10 minutes. At this period, please observe the current change of control panel and observe gate of die.

After grinding and lubricant the mold, we can enjoy the ordinary pellet making.

GET IN TOUCH WITH US